We lift your business

Producten

Klik hier voor al onze productenWhat makes a Backsaver unique

Key Features

Flexibility

Flexibility

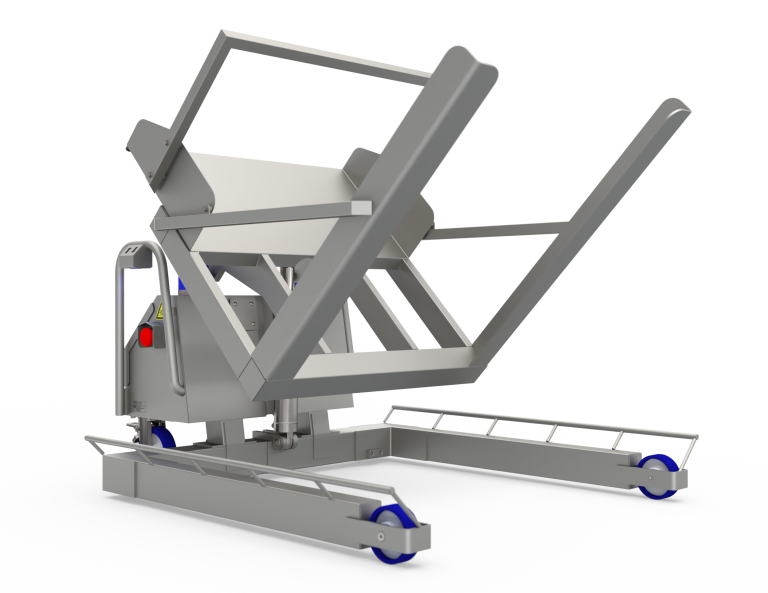

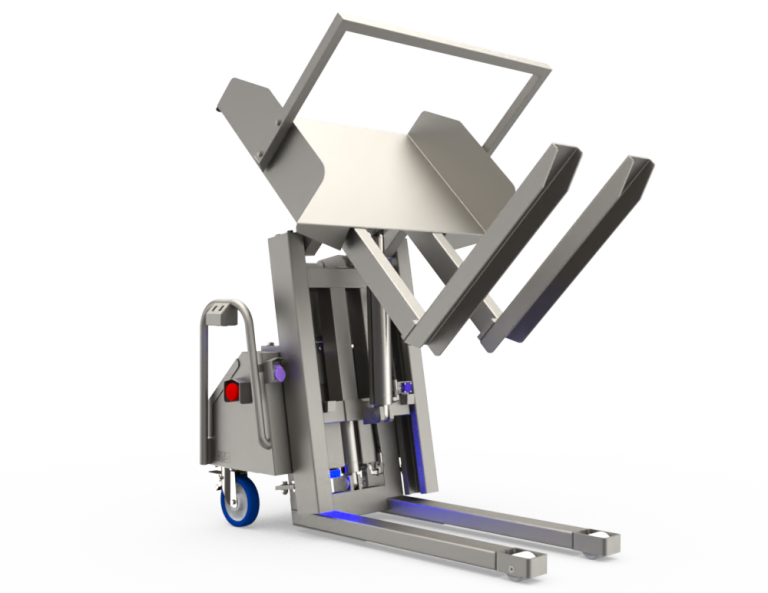

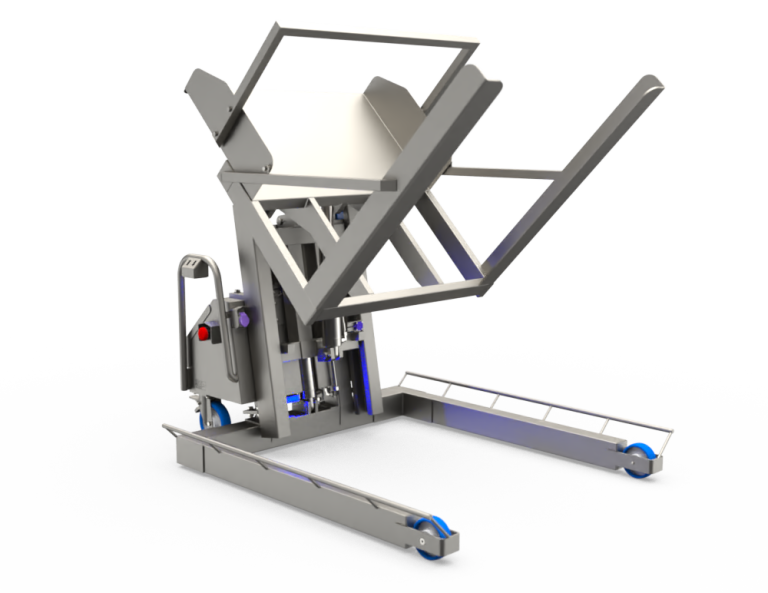

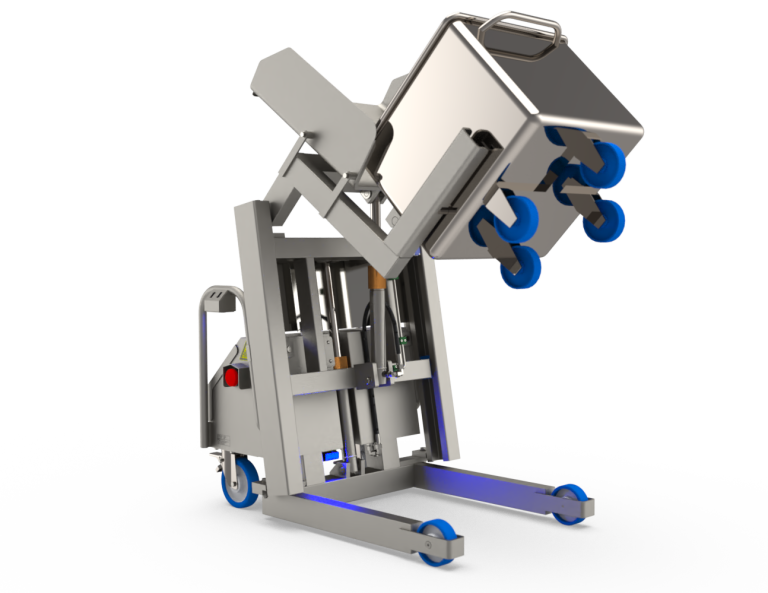

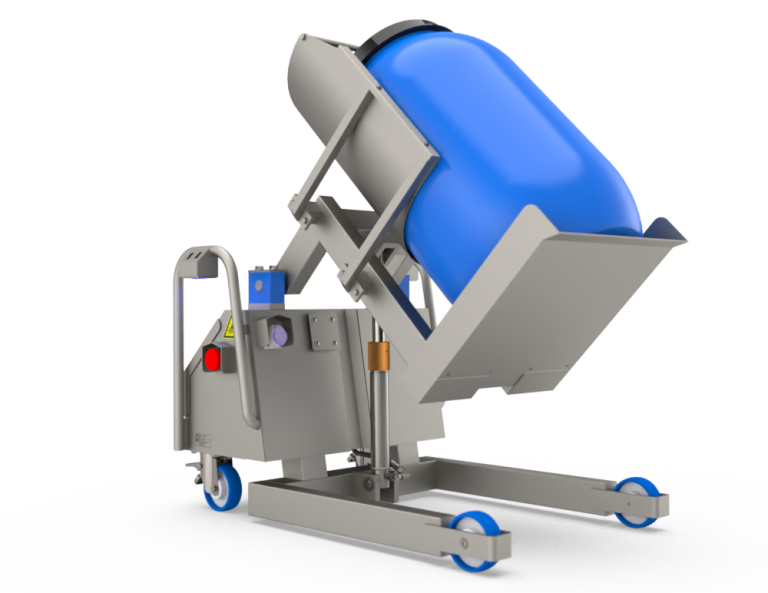

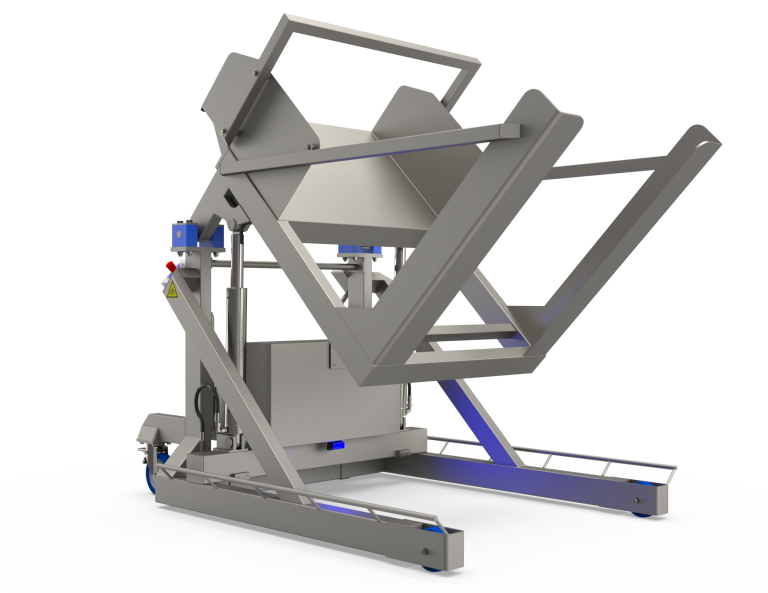

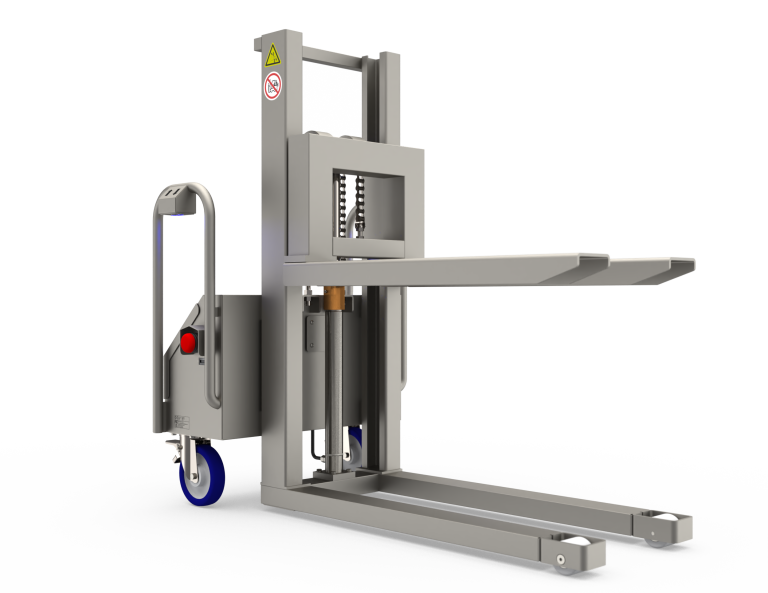

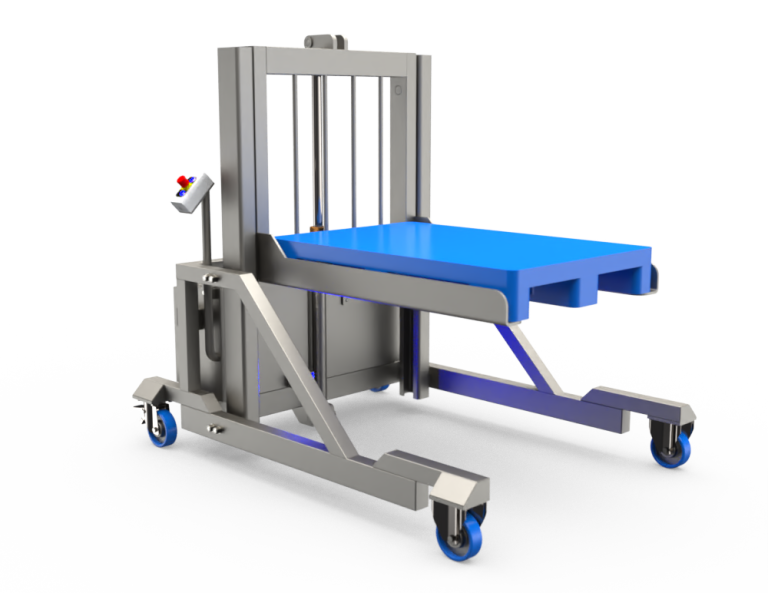

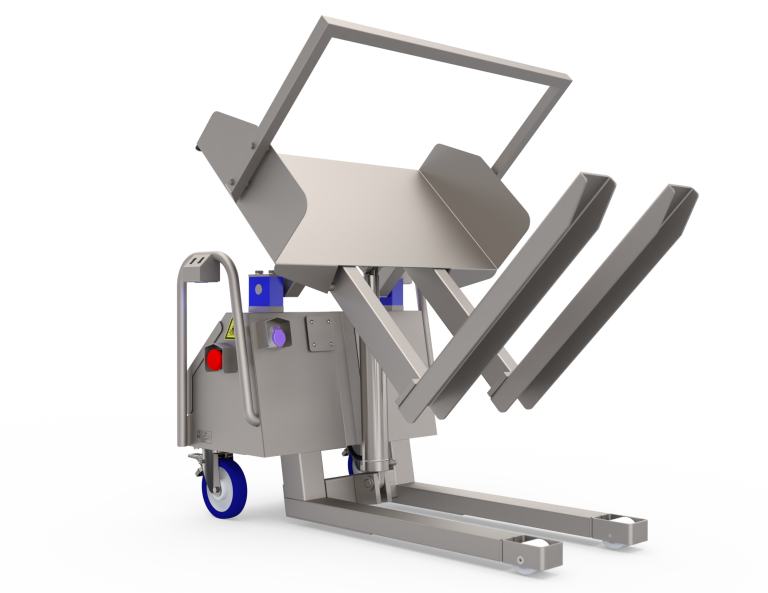

Backsaver manufactures stainless-steel lifting and tipping equipment for the food industry. First, we select a standard machine type and reconfigure it to meet your requirements. Whether your product is meat, fish, dairy or fruit, the Backsaver will suit it perfectly.

Lifting Your Business

Lifting Your Business

Regardless of what kind of container is used for your products (big boxes, combo bins, crates, buggies, tubs, barrels, etc.), we can deliver a Backsaver solution to enhance production and ensure success.

Stainless Steel

Stainless Steel

Backsavers are constructed from the AISI304 and AISI316 grades of stainless steel for an optimal quality/price ratio with maximum hygiene and food safety. Moreover, they’re approximately 90% recyclable.

Easy to Use

Easy to Use

Backsavers are simple and user-friendly. They’re easy to maneuver, and you can operate one from either side. Moreover, each unit has a powerful, deep-cycle battery that eliminates the need for a power cord. So, you can use the Backsaver throughout your facility.

Hygiene

Hygiene

Hygiene is a key concept in the machinery design engineering and manufacture for the food industry. All our machines consist of components and assemblies designed to ensure consistent product hygiene and employee safety. Backsaver machines are IP56-rated and allow cleanup with a regular pressure washer.

Custom-Made in Holland

Custom-Made in Holland

Backsavers stainless-steel lifting and tipping machines are designed and manufactured with more than 30 years of experience in the Netherlands at our in-house design engineering and production facility. Thanks to comprehensive customization, we can meet the requirements of any production facility.

What gives us direction

Our Mission & Vision

Work Hard, Lift Smart

Our mission is to build high-quality stainless-steel lifting and tipping machinery for the food industry, making it easy to enhance your production and minimize workplace injuries.

A Backsaver on Every Production Line

Our vision is to have one or more Backsavers at every facility in the global food industry.

Polski

Polski Italiano

Italiano Svenska

Svenska Nederlands

Nederlands Deutsch

Deutsch Français

Français Español

Español Русский

Русский 日本語

日本語 한국어

한국어