tailor made back saving machines

Case Studies

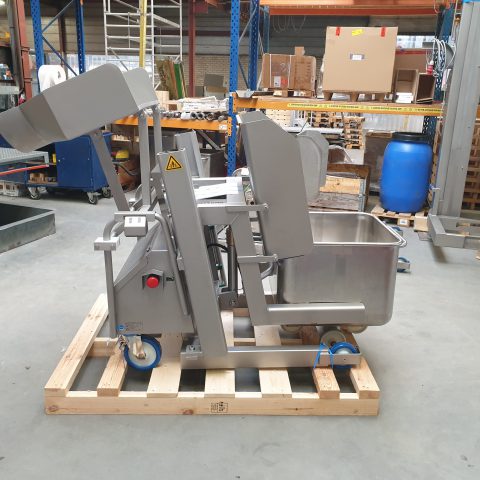

BSMCD Adjusted for tipping Octabins over the long side

In order for a customer specific request we’ve adjusted a BSMCD model to tipp Octabins over the long side of the pallet.

Due to the closed bottom on the long side it’s not easy to load these Octabins with a palletjack, therefore we’ve replaced the standard cornerprofiles with strengthened forks.

In this way the Octabin can be picked up on the long side without breaking the pallet. Combined with a chute shaped perfecty for their Octabins this solution is a perfect solution for them.

This Backsaver is equipped with a 2-handed control panel to minimalize the risks of injuries by the operator.

This Combo dumper tilts Octabins up to 1500KGs to 1485mm at an angle of 120⁰ !

If you have any questions regarding possibilities of our Backsavers feel free to contact us. We can customize all of our Backsavers to certain specifications!

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

BSMBR Filling 200/300 liter Buggies

In order to quickly fill your euro-normtrolleys/meat buggies we have developed a special discharge table which is able to fill 2 trolleys at the same time.

By using this extra deviding table the product will devide in both trolleys untill they’re full.

This option can be used for several Backsavers like the BSMST, BSMLT, BSMBR, BSMBRLT, BSMSD, BSMMD, BSMCD.

Optionally this can be upgraded with a liquid drain system in the Backsaver, bulkhead on the chute, etc.

Do you have a custom request for tipping/lifting bins/barrels/trolleys etc. Don’t hesitate to contact us!

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

BACKSAVER BSMST for filling Vaccuummachine Sideways

In addition of a customer-specific request, we have recently realized a solution for filling a vacuum machine. Because the customer has limited space in his production hall, we were asked to devise a solution in which the Backsaver is perpendicular to the vacuum machine.

By connecting a discharge table to the modified BSMST Backsaver, a buffer can be built up in the table in order to be able to fill the vacuum machine with product more quickly.

Previously, this was manually scooped out of the Dolav container, causing the employees to have back problems. Now all employees want to work at this station!

Of course, this is another custom Backsaver built specifically for this customer.

If you are looking for a similar solution, do not hesitate to contact us. We will be happy to advise you regarding your specific situation.

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

BSMNTLT For filling tumblers at various heights

In response to a number of customer requests for filling tumblers with trolleys, we have developed a new solution.

The existing option was to place a table in between tumbler and Backsaver which could be used as an extra slope. Main issue was the lack of space in a room full of tumblers so therefore we developed a new option for this need, the adjustable surge-chute!

In combination with a rubber seal as a closure in the existing chute and the adjustable added chute, customers can now save up to 100% of their product and brine (or marinade) while tipping it into their tumblers.

This option is adjustable for different Tumbler heights.

Keep in mind that 90% of are Backsavers are custom made, so is this one too.

If you are interested in a similar model, please don’t hesitate to contact us. Dimensions can be altered to certain maximum heights, but there’s a big possibilty we can make a fitting Backsaver solution for your needs as well!

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

BSMST For separating moisture and product

In response to customer-specific request, we have developed a retractable perforated stainless frame on our BSMST model.

This option is made to allow product to leak out in order to separate the moisture.

When the moisture has leaked away, the perforated plate can be extracted so that the product can (optionally) be tipped into another container/conveyor/buffer etc.

For this specific request we adapted our BSMST model for Seaplast tubs, but this can be adjusted for different bin sizes like Dolav, Bigbox, Combo, Euroformat as well.

This option can be adjusted to different Backsaver models, so if you are looking for a similar request, please contact us!

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

Polski

Polski Italiano

Italiano Svenska

Svenska Nederlands

Nederlands Deutsch

Deutsch Français

Français Español

Español Русский

Русский 日本語

日本語 한국어

한국어

![20211110_142720[1]](https://www.backsaver.nl/user-files/uploads/cache/20211110_1427201-scaled-pfuzvxwpqsm4p858henzc13di5c77alle128uducjk.jpg)