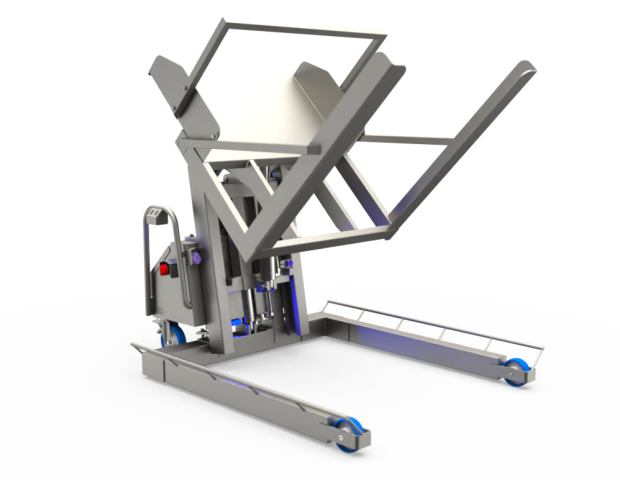

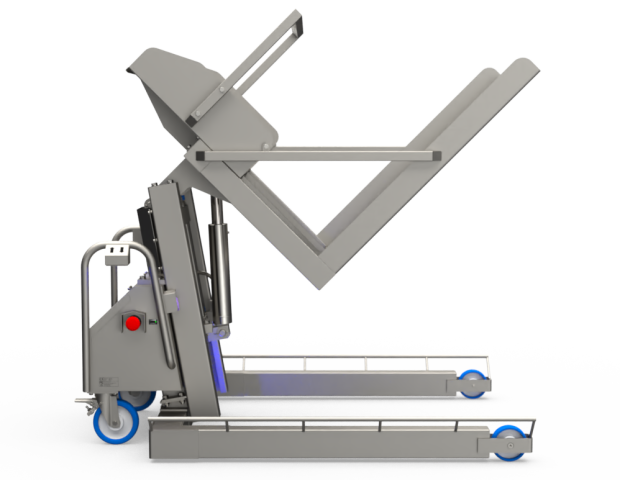

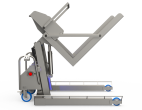

Backsaver BRLT Wide Lifter/Tipper

The Backsaver BRLT lifting/tipping machine is designed for emptying wide plastic bins, pallet crates and other large containers when the Backsaver BR tipper’s dumping height is insufficient. The BRLT machine is equipped with a van Oirschot specialty lift-and-tip system that makes it possible to raise a large, heavy bin to a certain height and then tilt it. Unlike LT, it is a wider and larger stationary machine that can be occasionally moved and easily accepts loads from pallet jacks, pallet trucks or forklift trucks.

Improved process: Backsavers for longer uptime in food processing

Backsavers are simple, easy-to-use machines that enhance production and reduce the risk of workplace injury. BRLT is ideal whether you work at a table, a process line or an elevated loading platform. Independent controls on both sides of the machine are reachable regardless of its actual position, thus eliminating all the extra walking around the machine to operate it, reducing downtime and making it a very popular solution at food-processing facilities. It can be easily integrated into a process line to discharge large bins onto a belt conveyor or into a screw conveyor’s hopper. It can also be used to fill other machinery, such as grinders, separators, tumblers, cutters, injectors and packers.

Health and enhanced productivity

This machine is designed to be installed at specific locations for emptying operations. When needed, it can still be occasionally relocated. A bin of product (meat, fish, vegetables, etc.) is loaded into the lifter/tipper with a pallet jack or forklift. The load is then raised and tilted in a single smooth motion until the product starts to come out or even further to the maximum set angle. Because manual lifting, crouching and bending are no longer necessary, the risk of back pain, strain and injury is reduced. Healthy personnel are happier, more efficient and productive, and throughput is maximized.

Powerful rechargeable battery

Backsavers are powered by rechargeable batteries, so they can be used everywhere on the work floor regardless of the power-supply location. The battery is suitable for operation in refrigerated areas and can be plugged in overnight for convenient charging. With a fully charged battery you can handle approximately 40 tons of products.

Operational safety: Unforced lowering signaled by light and sound

BRLT, with its two heavy-duty locking swivel casters mounted outside of the frame for maximum stability, can optionally be set to a tipping angle of up to 108 degrees while remaining stable and safe. Like other Backsavers, this machine is driven by twin hydraulic cylinders that use gravity for the lowering action. So, it’s very safe because it significantly reduces the risk that its moving parts might incur bodily injury. For even greater safety, it features an audible backup signal and a flashing LED beacon light that warn others about parts in motion, ensuring extra attention during operation.

Hygiene and food safety: Backsavers for direct food contact

Backsavers are developed especially for the food industry. They are safe to operate and suitable for direct contact with food products. These machines are stainless steel for easier cleanups and wash-downs making it possible to use power washers. BRLT has been engineered, designed and manufactured in the Netherlands since 2010.

Standard Features:

- Twin hydraulic cylinders (1 ea. for lifting and tipping)

- Backup sound alarm

- LED flashing beacon light

- Heavy-duty locking casters

- Powerful rechargeable battery

- Independent controls on each side

- Dead man’s (hold-to-run) buttons (Up/Down)

Available Options:

- Extended-stroke lifting cylinder for dumping at heights of up to 1410 mm at XXX degrees

- Tapered discharge chute / narrowed spout for improved product flow

- Extended discharge chute: up to 100 mm (4″) without changing the machine’s frame

- Raised discharge chute sides for improved product containment

- Adjustable, swinging or customized retaining bar position for various bin sizes

- Different max. tipping angles: 90, 100 and 108 degrees

- Plug-in (400 V) instead of battery-powered for stationary use

- Increased load rating: up to 1,100 kg / 2,425 lbs.

Need advice? Call us: +31 411 689 372

Because 90% of our machines are custom-made you might need some help in configuring the right Backsaver for your production areas. Don’t hesitate to call or send us an email: sales@backsaver.nl

All our machines are custom-made

to fit your facilities

Specifications:

*Applicable to standard bins. For other bin sizes, please, feel free to contact us.

- Approx. Dumping Height: 1,280 mm / 50,4" at 100 deg.

- Max. Bin Height: 1,000 mm / 40"

- Tipping Angle: 0-100 deg.

- Load Rating: 900 kg / 2,000 lbs

- IP Rating: IP56 (limited dust ingress; strong water jets, any direction)

- Power Source: 12-volt deep-cycle / semi-traction battery

- Approx. Machine Weight: 550 kg / 1,210 lbs

Markets served:

- Meat processing

- Fish processing

- Vegetable processing

- Fruit processing

- Mixing/blending

- Cheese processing

- Other dairy processing

Argentina:

Argentina:

Alfa Argentina S.A.

Barracas Capital Federal

Buenos Aires

Argentina

Tel: +54(0) 11 43012639

Web: http://www.alfaargentina.com

Australia:

Australia:

Global Machinery & Supplies

3 Albion Lane

2088 Mosman NSW

Australia

Tel: +61 29969 0370

Fax: +61 29969 0312

Web: http://www.globalms.com.au

Belarus:

Belarus:

Mirozdanie ALC

Babushkina 29/9

220024 Minsk

Belarus

Tel: +375 17 2 91 86 29

Web: http://mzd.deal.by

Belgium:

Belgium:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

E-mail: info@backsaver.nl

Web: https://www.backsaver.nl/

Canada:

Canada:

Dpec Food Solutions Inc.

6705 Tomken Rd, Unit 15

Mississauga (ON), L5T-2J6

Canada

Tel: +1 905-565-1500

Web: https://www.dpecfoodsolutions.ca

Chile:

Chile:

Alfa Chilena S.A.

Dirección: Las Américas 700

Cerrillos | Santiago | Chile

Chile

Tel: +56 (2) 288 99 000

Web: http://www.alfachilena.cl

Estonia:

Estonia:

Provitek Balti Oü

Reti tee 4

Peetri alevik

Rae vald

75312 Harjumaa

Estonia

+372 6393152

Web: http://www.provitek.fi

Finland:

Finland:

Hagson-Provitek Oy

c/o Knitter Business Park

Kutojantie 6-8

02630 Espoo

Finland

Office +358(0)9 439 307 0

Web: http://www.provitek.fi

France:

France:

Technocarne

1, route du Golf

67610 LA WANTZENAU

France

Tél. (33) 03 88 33 09 33

Fax : (33) 03 88 83 00 11

Web:http://www.technocarne.com

Germany:

Germany:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

E-mail: info@backsaver.nl

Web: https://www.backsaver.nl/

Greece:

Greece:

Vamvacas Industrial Equipment SA

Iceland:

Iceland:

Klaki stálsmiðja

Hafnarbraut 25

200 Kopavogur

Iceland

Tel: +354-554 00 00

Fax: +354-554 41 67

Web: http://www.klaki.is

Ireland:

Ireland:

Shareteq Ltd Ireland

1st Floor, 6 Lapps Quay

Cork

Ireland

T: +44-1775-710100

E: info@shareteq.com

Web: http://www.shareteq.com

Italy:

Italy:

Cavalli Meat Processing Machinery s.r.l.

Via XXV Aprile 18

43035 Felino (Parma)

Italy

tel. +39-0521-836670

fax +39-0521-837647

Web: http://www.cavallimpm.it

Japan:

Japan:

Radix Co. Ltd.

Ariake(keiwa) Bd. 3-12-16 Turumaki

154-0016 Setagaya-ku Tokyo

Japan

Tel: +81-3-5426-7183

Web: https://radix-inc.co.jp/

Latvia:

Latvia:

Regrand

26, Ganibu Dambis Str.

LV-1005 Riga

Latvia

Tel: +371 673 95339

Web: http://www.regrand.eu

Lithuania:

Lithuania:

Travalsa UAB

Vilniaus 21pšt.,p/d Nr.2762

LT-08018

Lithuania

Tel: +370 680 1077

Fax: +370 521 524 44

Moldova:

Moldova:

Tara.md Moldava Packing Site

str.T.Vladimirescu 8/1, etajul 4

Chisinau

Moldova

Tel: +373 78080914

Web: http://www.tara.md

Netherlands:

Netherlands:

Backsaver Manufacturer

Kruisbroeksestraat 17

5281 RV Boxtel

the Netherlands

Tel: +31 411 689 372

Web: https://www.backsaver.nl

New Zealand:

New Zealand:

Global Machinery & Supplies

2B Glover Street

2088 Mosman NSW

Australia

Tel: +61 29969 0370

Fax: +61 29969 0312

Web: http://www.globalms.com.au

Poland:

Poland:

Brokelmann Sp. z o.o.

56-300 Milicz

ul. Stawna 6

Poland

tel./fax +48 71 38 42 584

Web: http://www.brokelmann.pl

Slovakia:

Slovakia:

PQS s.r.o.

Stará Vajnorská 37

831 04 Bratislava

Slovakia

tel/fax. +42 12 446 33 141

Web: www.1pqs.sk

South-Africa:

South-Africa:

Gerber Fresh

Unit 2, 81 Falcon Crescent,

Capital Hill Commercial Estate,

Cr R 101 & Le Roux Drive, Midrand

South Africa

Tel +27 (0) 10 001 5222

Web: http://www.gerberfresh.co.za

Korea, Republic of:

Korea, Republic of:

Young Dong E&TS

991-4, Shinwol-dong

Yangchon-gu, Seoul

Korea

Tel: +82 2 2695 6915

Web: http://www.ydents.net

Switzerland:

Switzerland:

Max Urech AG

Lager- und Fördertechnik

Parallelstrasse 4

5606 Dintikon

Switzerland

Tel: +41 56 616 70 10

Web: http://max-urech.ch

Turkey:

Turkey:

Bemak Makina

Perpa Ticaret Merkezi A Blok

Kat:5 No:85 Okmeydanı

Şişli, İSTANBUL

Turkey

Tel: +90 212 210 55 30

Web: http://www.bemakmakina.com.tr

United Kingdom:

United Kingdom:

Shareteq Ltd

PO Box 1002

Spalding

PE11 1WE (England)

United Kingdom

Tel: +44-1775-710100

Web: http://www.shareteq.com

United States of America:

United States of America:

MID-WEST:

Premier Handling Solutions

1415 Davis Road

Elgin (IL) 60123

United States of America

Tel: +1 800-404-2311

Fax: +1 847-278-2310

http://www.phsinc.com

Can't find a reseller in your area? Please call our headquarters: +31 411 672 652

Are you interested in selling our products? Do you want to become a reseller? Make people lift smart! Please send us an e-mail: info@backsaver.nl

Polski

Polski Italiano

Italiano Svenska

Svenska Nederlands

Nederlands Deutsch

Deutsch Français

Français Español

Español Русский

Русский 日本語

日本語 한국어

한국어

Russia:

Russia: Spain:

Spain: